The digital transformation era is opening new horizons by placing humans at the center of innovation, fostering resilient operations and striving for a greener tomorrow.

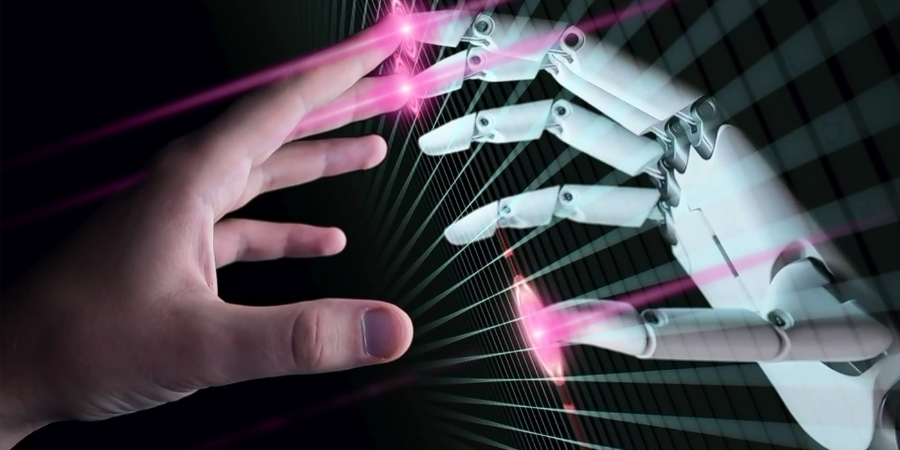

The ongoing fourth industrial revolution, where machines are dominating the industrialization scene, is being challenged by the concept of bringing people back to production and letting humans and machines work collaboratively.

The concept of Industry 5.0 aims to reverse the dehumanization of the industry and address the challenges associated with human-machine interaction and skills-building. The crucial role of man in society is amplified as an important factor that can lead to sustainable development. Thus, Industry 5.0 makes production more competitive in the long run by integrating three core elements: humanity, sustainability and resiliency.

Perhaps the greatest takeaway from the Industry 4.0 era was the understanding that technology alone does not work. Instead, the levels of collaboration between people and machines will strengthen with automation and machine intelligence, including robots working in support of the human workforce or manufacturing output.

In its entirety, Industry 5.0 reflects a shift from focusing on social economic value and strictly individual welfare to instead promoting overall well-being.

Cornerstones

It is evident that Industry 5.0 complements and extends the current Industry 4.0 paradigm, putting the advances in digitization, information systems and automation at the service of society. With real collaboration between machines, people and companies, a more global, integrated and innovative long-term vision can be fulfilled. Once organizations adapt to becoming more human-centric, resilient and sustainable, we can expect better solutions to emerge.

- Human-Centric

The vision of an innovative, resilient, socio-centric and competitive industry has been labeled as Industry 5.0. This era’s products and services are personalized and respond to human needs. Instead of the mindset that technology will replace humans, Industry 5.0 reiterates that there will be a fusion of skills between humans and technology for the mutual benefit of industry and industry workers.

Stimulated by Industry 4.0, Society 5.0 is envisioned to have humans at the center of innovation, technological transformation and industrial automation. People are known as multitaskers with a good sense of reasoning and empathy. On the other hand, machines can augment these skills, identify pattern recognition and assist in automating repetitive and time-consuming tasks.

In reality, not everything can be automated. This is where the debate over human factors comes into play in cases like autonomous cars, as the power of human cognitive and analytical capabilities remains irreplaceable. Rather than thinking of what we can do with new technology, we should consider what the technology can do for us.

By refocusing the process on the workforce and the customer, we can adapt existing technology to become more flexible and conformable, creating agile solutions. The key to Industry 5.0 success is not the technology but rather the people who use it.

With this in mind, attracting and retaining talent has become a considerably more important undertaking; putting the user at the center of industrial tech adoption can address labor demands and fully leverage human potential.

As a result, we can reposition human workers in manufacturing from assembly line processes and other repetitive tasks to more creative assignments that require their skills in problem-solving and intuition.

Industry 5.0 requires the proper training, foresight and implementation that will best equip workers with the knowledge to use the new technologies. Industry 5.0 principles and technologies provide a more progressive and interesting working environment that can lead to increased employee satisfaction and company loyalty.

- Resilient

In industrial production, being resilient refers to the robustness of operations — the certainty that they can withstand any possible disruptions and provide and support critical infrastructure in times of crisis. Geopolitical shifts such as the ongoing Russia-Ukraine war and health pandemics like COVID-19 highlight the fragility of current global supply chain production.

Industry 5.0 technologies are playing an important role in the development of industrial agility and resilience through comprehensive data gathering, flexible processes, automated risk analysis and enhanced security.

It is a must to have a fully-functional value chain at all times, particularly in verticals that serve basic human needs. The massive scale of supply chain disruption we have observed recently has made it clear that manufacturers should prioritize operational resilience moving forward.

- Sustainable

Industry 5.0 helps people understand that technology is essential to developing and engaging in sustainable practices, protecting the world’s ecosystems and making the best use of available resources.

Developing circular processes that involve reusing, repurposing and recycling can positively impact the environment. Sustainability means reducing energy consumption and greenhouse emissions, and technologies like AI and additive manufacturing can play a large role here.

ESG corporate responsibility goes beyond taking steps to reduce negative environmental impacts and suggests that their manufacturers become part of the solution. The production of devices and equipment should be done in a sustainable manner for maximum cost-efficiency and eco-friendliness.

As organizations’ digital systems become more robust and modular, they will have the flexibility to choose more sustainable options. The adoption of Industry 5.0 practices that maximize the time, energy and efforts of both humans and machines will promote the economic performance of industries while ensuring environmental sustainability.

Enablers

As the post-pandemic period unfolds for us, the concept of Industry 5.0 is gaining parallel momentum. Seen as the future of industrial automation, the technological side of robots, smart machines, IoT, AI and big data is balanced with more focus on sustainability, resilience and the enhancement of human talent.

According to the European Commission, human-centric solutions and human-machine interaction, as well as bio-inspired technologies, support the Industry 5.0 concept. These include, but are not limited to, digital twins, collaborative robots, VR/AR, automatic speech and gesture recognition and tracking devices.

Humans working alongside smart machines require and generate a large amount of data. Because of this, the adoption of 5G and the cloud will grow exponentially, transforming the way business is done around the world.

Without a doubt, connectivity is at the heart of Industry 5.0. Advanced automation will be supported by high-speed data exchange and seamless integration of technologies. This generation of evolved machines is equipped with sensors, actuators and AI-powered controllers that allow them to work next to humans in a safe and harmonious manner.

5G networks can support the use of advanced robotics and AI in manufacturing, as well as the use of remote and mobile technologies to be more responsive to changing market conditions.

More importantly, by enabling faster and more reliable communication and data transfer, 5G can help manufacturers optimize their operations and increase overall productivity.

On the flip side, smart manufacturing utilizes the cloud for robust access control and usage of manufacturing resources across various places. The industrial cloud is a virtual environment that provides a supportive environment for applications and APIs. As edge computing becomes more prevalent, the amount of data transferred to the central server lessens, thus improving efficiency and augmenting the storage for other industrial activities.